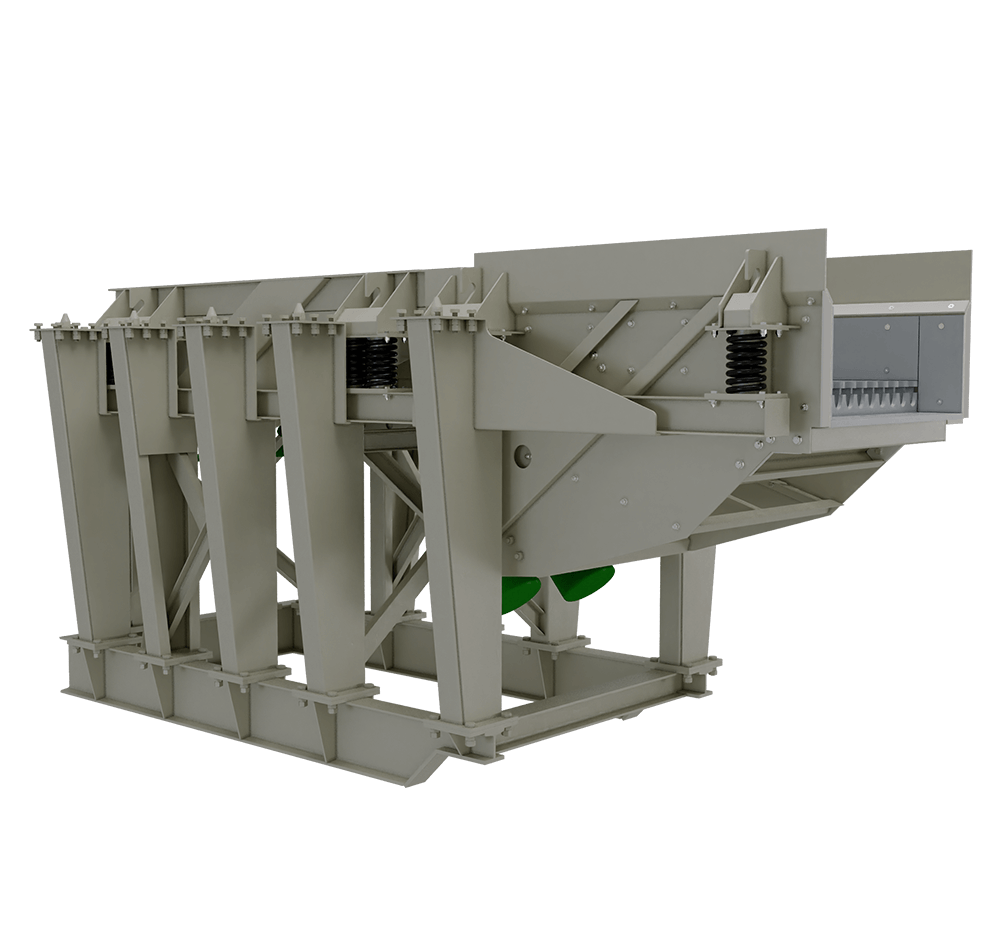

Reciprocating feeders are ideal options to be used for humid and sticky materials. They are suitable for loading heavy materials from high positions, as there is always material existing on the feeder. The system is formed by a carriage that is produced with thick body sheets, is coated with a thick wear-resistant sheet, and is moving back and forth by a hydraulic piston on construction machinery carrying a set of bearings that do not require maintenance or lubrication.

The system includes the hydraulic piston drive pump, the valve group, and the power system with the oil tank. The feed dosage of the feeder can be adjusted remotely by changing the stroke rate and the speed of the piston.

Material that is loaded at the back of the carriage moves forward by the forward motion of the carriage during its back and forth movement.

In the meantime, the material inside the hopper fills in the gap formed at the back of the carriage. When the carriage moves back; as the gap at the back is filled, the material at the front moves forward with a stroke distance.